WHAT IS FUEL MANAGEMENT SYSTEM?

29.08.2023

29.08.2023

WHAT IS FUEL MANAGEMENT SYSTEM?

It refers to the systems that manage fuel pumps. These systems can be wired for locations with suitable wiring infrastructure or wireless options for locations without wiring. They allow the operations performed at the pump to be controlled through software and hardware. This includes pump sales, unit price management, shift applications, as well as managing pump attendants and customers.

It is the most crucial component of fuel station automation that increases station efficiency. Through computer-based control, it completely eliminates the risk of erroneous calculations or reporting. Historical records maintained by the system provide convenience in station management and enhance efficiency. Integrating the automation system with well-known pump brands is an important aspect. Make sure that the automation system can integrate with your pumps when selecting one.

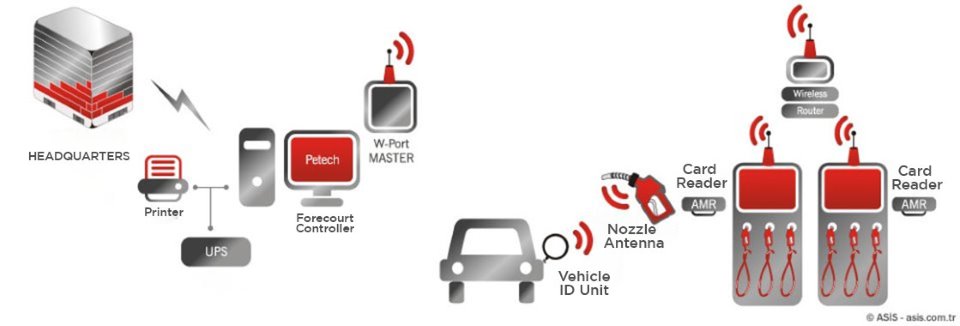

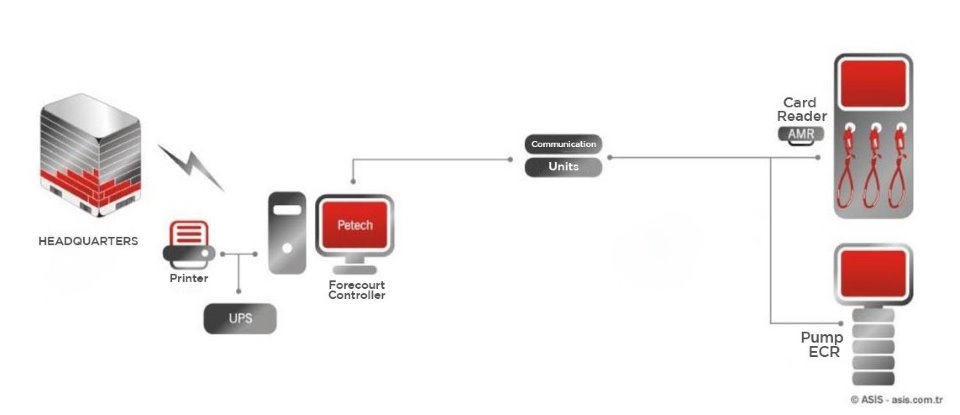

HOW DOES THE SYSTEM WORK?

In the fuel pump automation system, all pumps are connected to a PC located in the station building, usually in the attendant's room, through an automation cabinet. Once connected to the automation, automation parameters are set in the pumps' control units, and the pumps are switched to automation mode. After entering this mode, the pumps won't dispense fuel without receiving commands from the automation system.

The pump automation software installed within the automation manages all connected pumps. Once the system is installed, wiring and connections are established; all pumps, nozzles connected to the pumps, fuel types sold at the nozzles, and pump attendant cards are registered in the automation software. This enables the software to know which pump is dispensing which fuel type from which nozzle. Readers attached to the pumps and pump attendant cards are also registered in the system. These configurations are made in a menu within the software that is protected by an administrative password. After the systems are activated, these passwords are provided to station managers. From then on, the responsibility for defining and using the system lies with the station manager.

Before fuel is dispensed to a vehicle, the attendant places the nozzle into the vehicle's tank and scans their card on the reader located on the pump. Through this process, information is transmitted to the automation system regarding which pump and nozzle were used, as well as which attendant card was scanned. The automation system records this information and verifies the attendant's identity. If the attendant is registered in the system, the system electronically sends the command to "dispense fuel" to the pump. Fueling the vehicle begins. After refueling, the pump sends information about the amount of fuel dispensed, the total cost, and the unit price to the automation system. The automation system combines this sales data with the attendant's information and records the transaction in the database.

The following information is available for each sale made at the pump:

-

Date and time of the sale

-

Pump number

-

Nozzle number

-

Fuel type

-

Unit price

-

Total amount

-

Liters dispensed

-

License plate of the vehicle being fueled

-

Pump attendant's identification

The automation system does not intervene in the data received from the pump. It simply records the sales data exactly as received. This means that pump automation systems primarily control pumps and gather data from them, but they do not modify the data generated by the pumps. Rounding of the final amount in pump sales is done by the pump itself, not the automation system.

In automation systems, the ID cards used can be assigned to attendants individually, or cards can also be assigned to credit customers. When an ID card is designated as an attendant card, the system treats all transactions using that card as cash sales and automatically attributes those sales to the attendant in shift reports. This way, during shift handover, station managers can see how much fuel each attendant sold and how much money they need to hand in. If an ID card is assigned as a credit customer card, the system records the customer's company information, the license plate of the vehicle associated with the card, and the fuel type that vehicle uses. Multiple vehicles can be associated with a single credit customer. When a credit customer arrives at the station, the attendant scans their credit card on the reader, not the attendant card. The system recognizes the card as a credit card and automatically records the transaction as a credit sale.

Station managers request cash payments from attendants based on shift reports. Attendants provide both the cash they collected and credit card slips to the station manager. Since credit card transactions are done through a POS device not integrated with the automation system, all attendant sales are treated as cash sales within the system. The separation between cash and credit card sales is done by station managers.

For credit sales, the station manager generates reports for the relevant credit customers in the system and invoices them according to the agreements in place. However, official invoicing, account reconciliation, and other accounting processes are not conducted through the automation system. As the automation system is not an accounting system, these accounting processes are manually performed by transferring data from the reports to another system or structure.

ADVANTAGES:

Real-Time Monitoring: The fuel pump automation system allows tracking the amount of fuel and the type of fuel a customer purchases through the fuel station's interface. This real-time monitoring enhances transparency and management control.

Centralized Price Control: One of the advantages of the pump automation system is that unit prices can be changed centrally through the system interface, rather than needing to make changes directly at each pump. This streamlines the process of adjusting fuel prices.

Integrated Customer Recognition: When integrated with customer recognition systems, the pump automation system enables self-service fueling. Customers can perform fueling operations themselves using their recognized profiles, enhancing convenience and efficiency.

Shift Changes: After shift changes are introduced into the system, shift handovers become much smoother. The automation system facilitates easy transition between different shifts, reducing the potential for errors during this process.

Account Customization: The system allows various customizations to be applied to customer accounts, such as discounts and limitations. These configurations can be managed through the automation system, providing flexibility and control.

Efficiency and Accuracy: The automation system performs all calculations without errors and in a short amount of time. This significantly increases the efficiency of a station. For instance, a manual shift change process at a station might take 20-35 minutes, while with the automation system, it can be reduced to 10-15 seconds.

In summary, a fuel pump automation system offers numerous advantages such as real-time monitoring, centralized price control, customer recognition integration, streamlined shift changes, customizable account settings, and overall enhanced efficiency and accuracy in station management.

APPLICATION AREAS

Fuel pump automation systems can be used in various areas, including:

-

Fuel stations

-

Construction sites

-

Mobile stations

-

Tanker filling facilities

-

Municipal fueling stations for public vehicles

-

Military units

-

Factories

-

For any location where fuel dispensing occurs.

For more information about Fuel Automations produced by Asis, CLICK HERE.